- 您现在的位置:买卖IC网 > Sheet目录1014 > Y92B-A250 (Omron Electronics Inc-IA Div)HEATSINK SSR FOR G3NA SERIES

�� �

�

�

�Operating and Storage Locations�

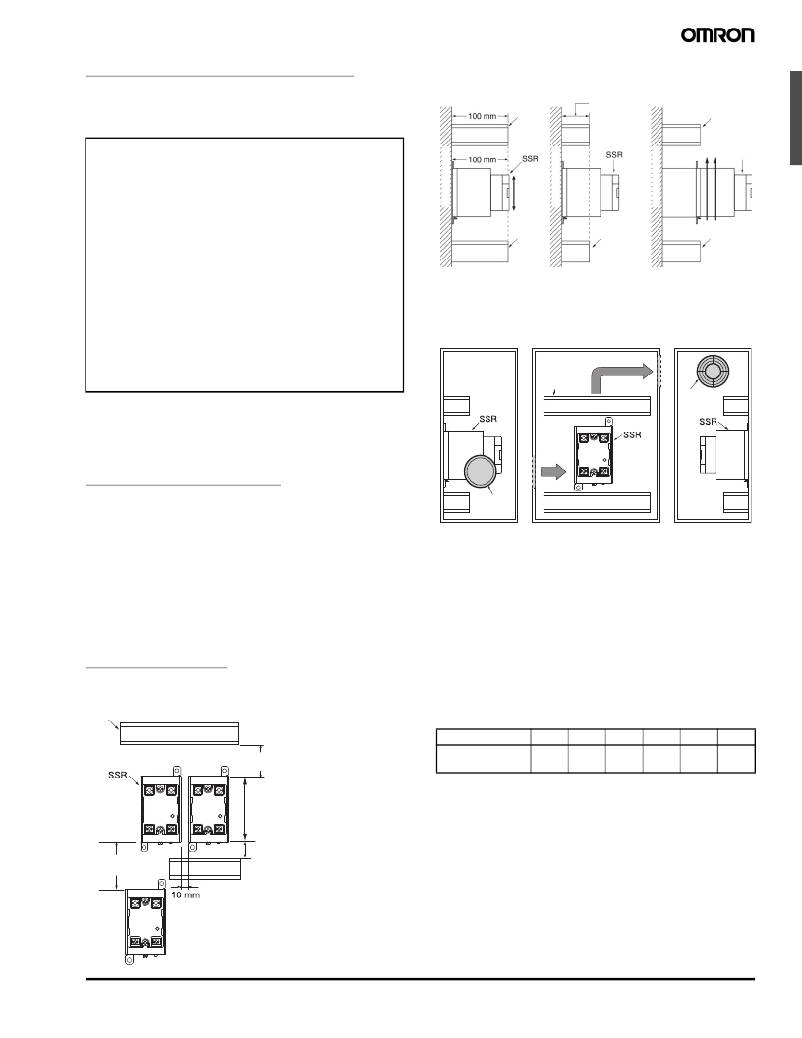

�Relationship� between� SSRs� and� Duct� Height�

�Do� not� use� or� store� the� G3NA� in� the� following� locations.� Doing� so�

�may� result� in� damage,� malfunction,� or� deterioration� of� performance�

�characteristics.�

�Incorrect� Example�

�D� u� ct�

�Countermeasure� 1�

�50� mm� max.�

�(A� height� of� no�

�more� than� half�

�Countermeasure� 2�

�D� u� ct�

�the� SSR's� height�

�?� Do� not� use� or� store� in� locations� subject� to� direct� sunlight.�

�?� Do� not� use� in� locations� subject� to� ambient� temperatures� outside�

�the� range� –20� to� 60� °� C.�

�?� Do� not� use� in� locations� subject� to� relative� humidity� outside� the�

�range� 45%� to� 85%� or� locations� subject� to� condensation� as� the�

�V� ertical�

�direction�

�is� recommended.)�

�Base�

�Airflo� w�

�SSR�

�result� of� severe� changes� in� temperature.�

�?� Do� not� store� in� locations� subject� to� ambient� temperatures� outside�

�the� range� –30� to� 70� °� C.�

�D� u� ct�

�D� u� ct�

�D� u� ct�

�?� Do� not� use� or� store� in� locations� subject� to� corrosive� or� flammable�

�gases.�

�?� Do� not� use� or� store� in� locations� subject� to� dust� (especially� iron�

�dust)� or� salts.�

�?� Do� not� use� or� store� in� locations� subject� to� shock� or� vibration.�

�Do� not� s� u� rro� u� nd� the� SSR�

�w� ith� d� u� cts,� other� w� ise� the�

�heat� radiation� of� the� SSR�

�w� ill� b� e� ad� v� ersely� affected.�

�Use� short� d� u� cts.�

�If� the� d� u� cts� cannot� b� e�

�shortened,� place� the� SSR� on�

�a� metal� b� ase� so� that� it� is� not�

�s� u� rro� u� nded� b� y� the� d� u� cts.�

�?� Do� not� use� or� store� in� locations� subject� to� exposure� to� water,� oil,� or�

�chemicals.�

�?� Do� not� use� or� store� in� locations� subject� to� high� temperatures� or�

�high� humidity.�

�?� Do� not� use� or� store� in� locations� subject� to� salt� damage.�

�?� Do� not� use� or� store� in� locations� subject� to� rain� or� water� drops.�

�■� Precautions� for� Correct� Use�

�Please� observe� the� following� precautions� to� prevent� failure� to� oper-�

�ate,� malfunction,� or� undesirable� effect� on� product� performance.�

�Before Actual Operation�

�1.� The� G3NA� in� operation� may� cause� an� unexpected� accident.�

�Therefore� it� is� necessary� to� test� the� G3NA� under� the� variety� of�

�conditions� that� are� possible.� As� for� the� characteristics� of� the�

�G3NA,� it� is� necessary� to� consider� differences� in� characteristics�

�between� individual� SSRs.�

�2.� Unless� otherwise� specified,� the� ratings� in� this� catalog� are� tested�

�values� in� a� temperature� range� between� 15� °� C� and� 30� °� C,� a� relative�

�humidity� range� between� 25%� and� 85%,� and� an� atmospheric� pres-�

�sure� range� between� 88� and� 106� kPa� (standard� test� conditions�

�according� to� JIS� C5442).� It� will� be� necessary� to� provide� the� above�

�conditions� as� well� as� the� load� conditions� if� the� user� wants� to� con-�

�firm� the� ratings� of� specific� G3NAs.�

�Mounting Method�

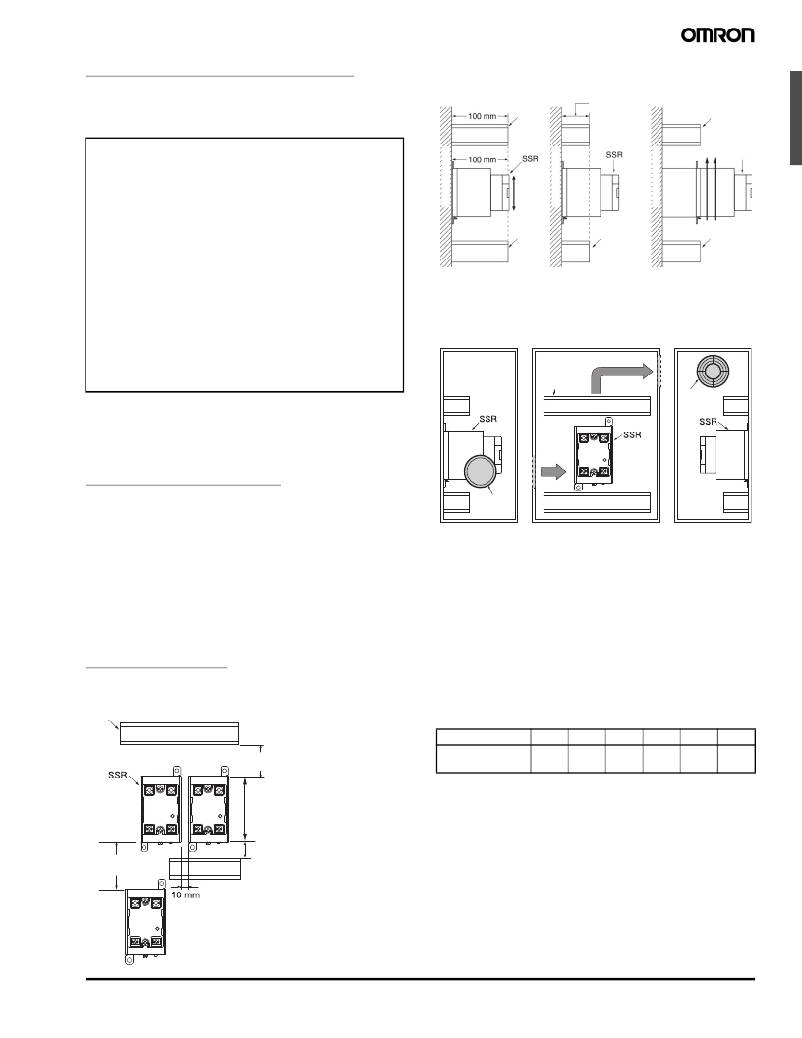

�SSR� Mounting� Pitch� (Panel� Mounting)�

�D� u� ct�

�Ventilation� Outside� the� Control� Panel�

�Be� a� w� are� of� airflo� w�

�D� u� ct�

�Ventilation�

�o� u� tlet�

�(axial� fan)�

�Air� inlet�

�If� the� air� inlet� or� air� outlet� has� a� filter,� clean� the� filter� regularly� to� pre-�

�vent� it� from� clogging� to� ensure� an� efficient� flow� of� air.�

�Do� not� locate� any� objects� around� the� air� inlet� or� air� outlet,� otherwise�

�the� objects� may� obstruct� the� proper� ventilation� of� the� control� panel.�

�A� heat� exchanger,� if� used,� should� be� located� in� front� of� the� SSRs� to�

�ensure� the� efficiency� of� the� heat� exchanger.�

�?� Please� reduce� the� ambient� temperature� of� SSRs.� The� rated� load�

�current� of� an� SSR� is� measured� at� an� ambient� temperature� of� 40� °� C.�

�?� An� SSR� uses� a� semiconductor� in� the� output� element.� This� causes�

�the� temperature� inside� the� control� panel� to� increase� due� to� heating�

�resulting� from� the� passage� of� electrical� current� through� the� load.� To�

�restrict� heating,� attach� a� fan� to� the� ventilation� outlet� or� air� inlet� of�

�the� control� panel� to� ventilate� the� panel.� This� will� reduce� the� ambient�

�temperature� of� the� SSRs� and� thus� increase� reliability.� (Generally,�

�each� 10� °� C� reduction� in� temperature� will� double� the� expected� life.)�

�Load� current� (A)�

�5A�

�10� A�

�20� A�

�40� A�

�75� A�

�90� A�

�60� mm� min.�

�Required� number�

�of� fans� per� SSR�

�0.08�

�0.16�

�0.31�

�0.62�

�1.2�

�1.44�

�Example:� For� 10� SSRs� with� load� currents� of� 10� A,�

�0.16� x� 10� =� 1.6�

�Vertical� direction�

�Thus,� 2� fans� would� be� required.�

�80� mm� min.�

�30� mm� min.�

�Size� of� fans:� 92� mm� 2� ,� Air� volume:� 0.7� m� 3� /min,�

�Ambient� temperature� of� control� panel:� 30� °� C�

�If� there� are� other� instruments� that� generate� heat� in� the� control� panel�

�other� than� SSRs,� additional� ventilation� will� be� required.�

�Solid� State� Relay�

�G3NA�

�481�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

ZXSC310EV

BOARD EVALUATION FOR ZXSC310E5TA

000-16300

CONN PLUG BNC RG-180B/U

000-36800

CONN JACK BNC STR CRIMP RG58,141

000-53175

CONN PLUG 7/8 TRIAX 21-529 CABLE

000-79875

CONN PLUG TNC CLAMP STR 58/U

000-86350

CONN JACK BNC BULKHD RG174 188

0001.1001.TR

FUSE 500MA 250V 5X20 FAST CERM

0001.1006

FUSE 1.6A 250V 5X20 FAST CERM

相关代理商/技术参数

Y92BN100

制造商:OMRON AUTOMATION AND SAFETY 功能描述:HEAT SINK TRACK MNT FOR G3NA SER 制造商:OMRON INDUSTRIAL AUTOMATION 功能描述:Solid State Relay, Heat Sinks

Y92B-N100

功能描述:散热片 TRK MT HEAT SINK G3N RoHS:否 制造商:Ampro By ADLINK 产品:Heat Sink Accessories 安装风格:Through Hole 散热片材料: 散热片样式: 热阻: 长度: 宽度: 高度: 设计目的:Express-HRR

Y92BN150

制造商:OMRON AUTOMATION AND SAFETY 功能描述:HEAT SINK TRACK MNT FOR G3NA SER 制造商:Omron Electronic Components LLC 功能描述:Heat Sink Passive Screw 1.38|C/W 制造商:OMRON INDUSTRIAL AUTOMATION 功能描述:Heat Sink Passive Screw 1.38°C/W

Y92B-N150

功能描述:散热片 TRK MT HEAT SINK G3N RoHS:否 制造商:Ampro By ADLINK 产品:Heat Sink Accessories 安装风格:Through Hole 散热片材料: 散热片样式: 热阻: 长度: 宽度: 高度: 设计目的:Express-HRR

Y92BN50

制造商:OMRON AUTOMATION AND SAFETY 功能描述:HEAT SINK TRACK MNT FOR G3NA SER 制造商:OMRON INDUSTRIAL AUTOMATION 功能描述:Solid State Relay, Heat Sinks

Y92B-N50

功能描述:散热片 TRK MT HEAT SINK G3N RoHS:否 制造商:Ampro By ADLINK 产品:Heat Sink Accessories 安装风格:Through Hole 散热片材料: 散热片样式: 热阻: 长度: 宽度: 高度: 设计目的:Express-HRR

Y92BN50V

制造商:Omron Corporation 功能描述:

Y92BP100

制造商:OMRON AUTOMATION AND SAFETY 功能描述:HEAT SINK 1.01C/W 450G FOR G3PB 制造商:OMRON INDUSTRIAL AUTOMATION 功能描述:Heat Sink Passive 1.01°C/W